LASER ENGAVING

Detailed instructions for DIY engraving:

principle

The 450nm blue laser has high directionality and high intensity. Through the optical system, the light spot is shaped and focused, so that the laser heat energy is focused on the surface of the processed article, and the laser heat energy is used to burn or make the engraving surface chemically change to produce engraving imprints, and then cooperate with the running track of the laser head to achieve laser engraving.

Material selection

Metal materials: such as stainless steel, copper, aluminum, etc. The blue laser effectively removes the anodized layer from the metal surface, exposing the underlying metal to form a high-contrast mark, suitable for high-precision engraving or marking.

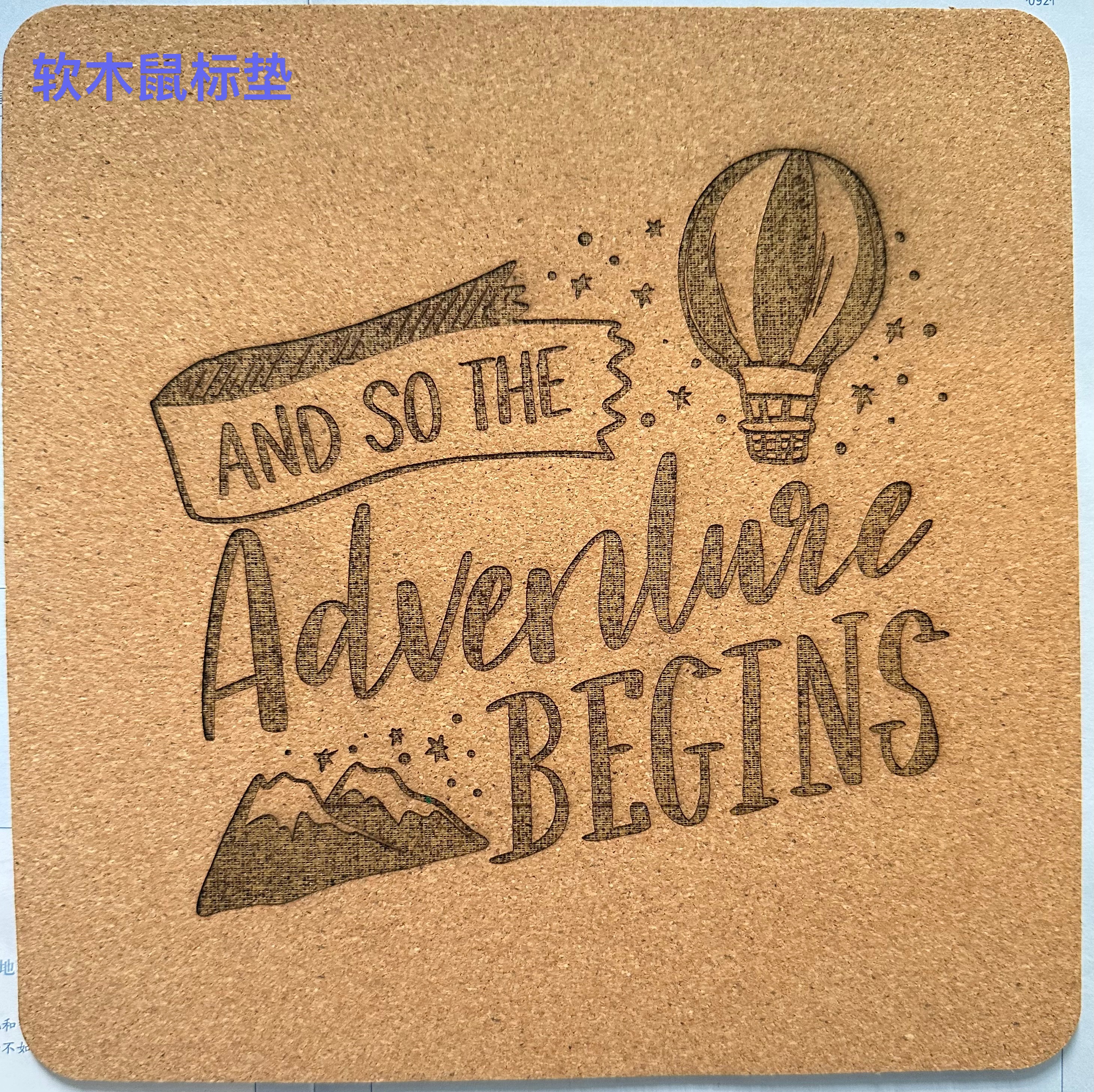

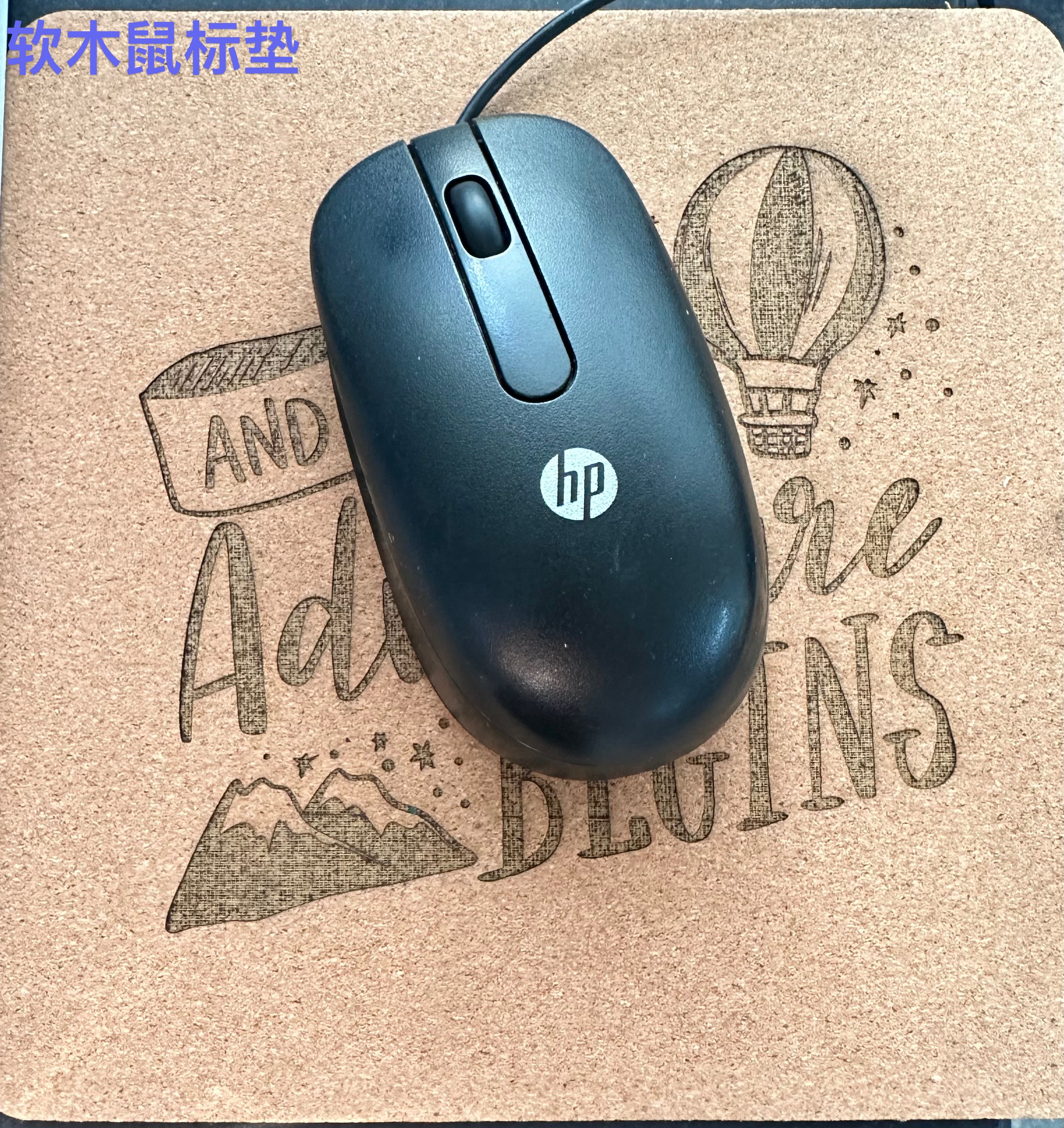

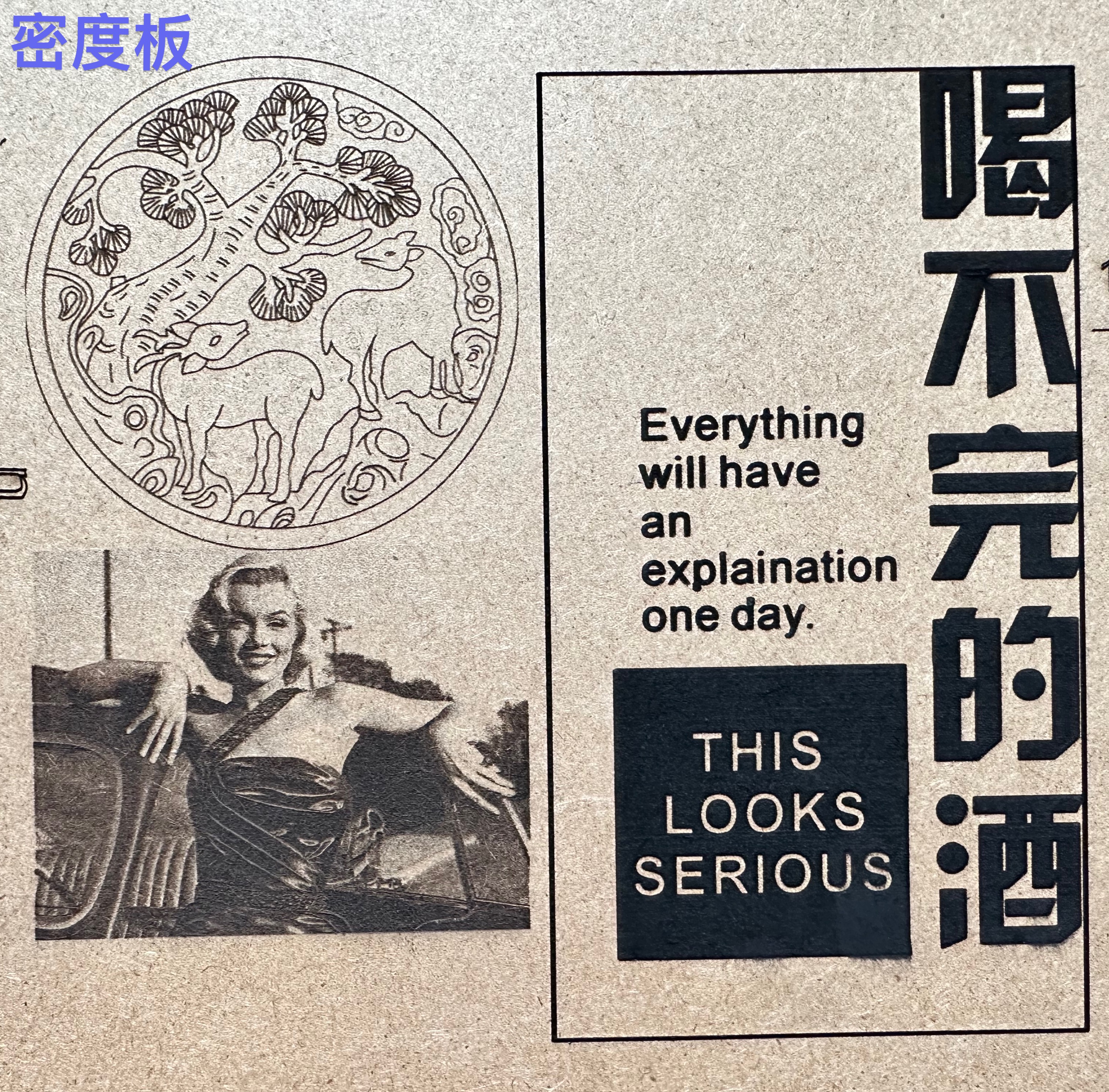

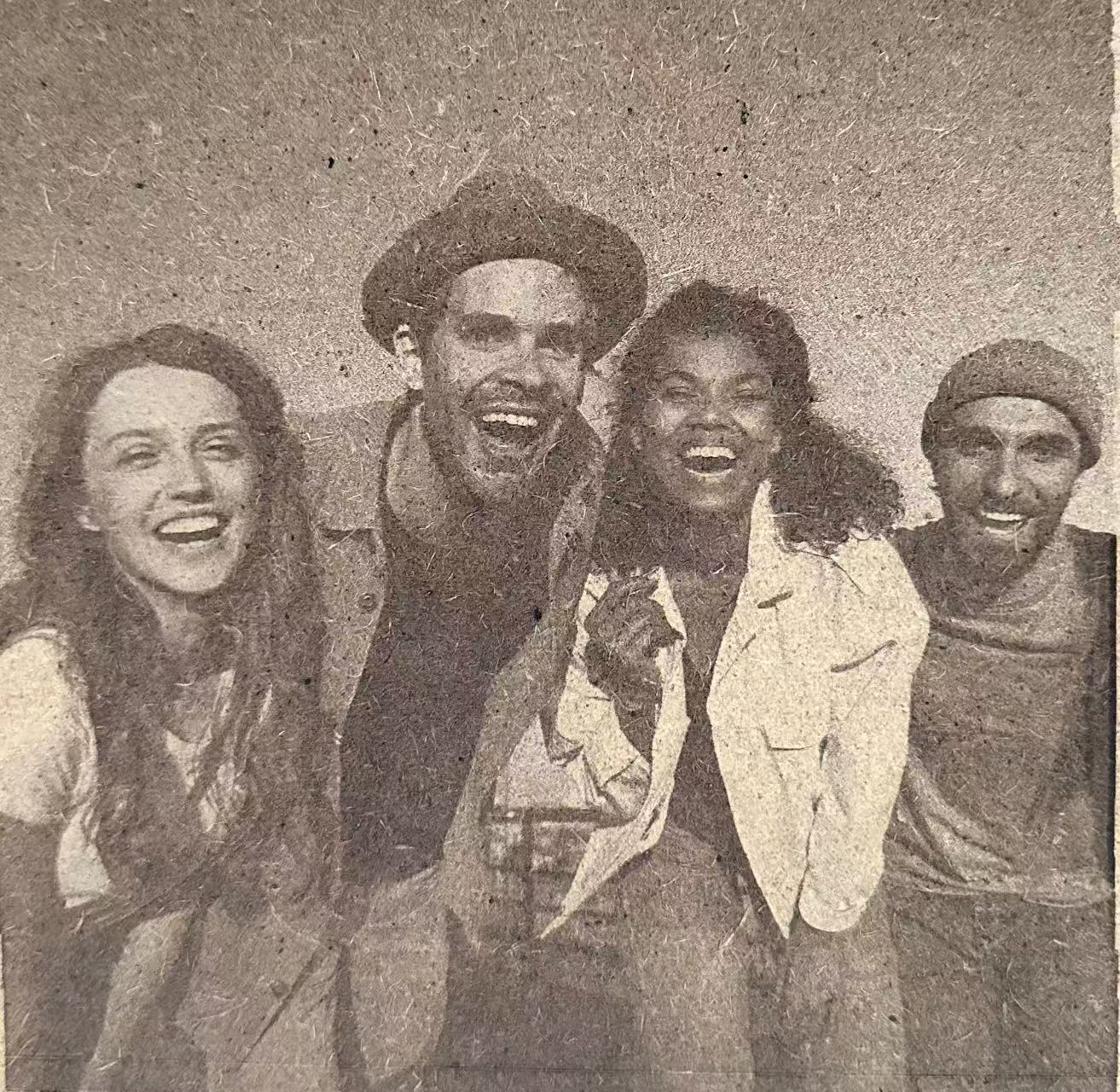

Organic materials: including leather, wood, paper, fabric, etc. These materials have good absorption of 450nm blue light and are easy to be laser engraved with clear patterns and text, but pay attention to controlling the laser power and speed during the engraving process to prevent the material from overheating, burning or deforming.

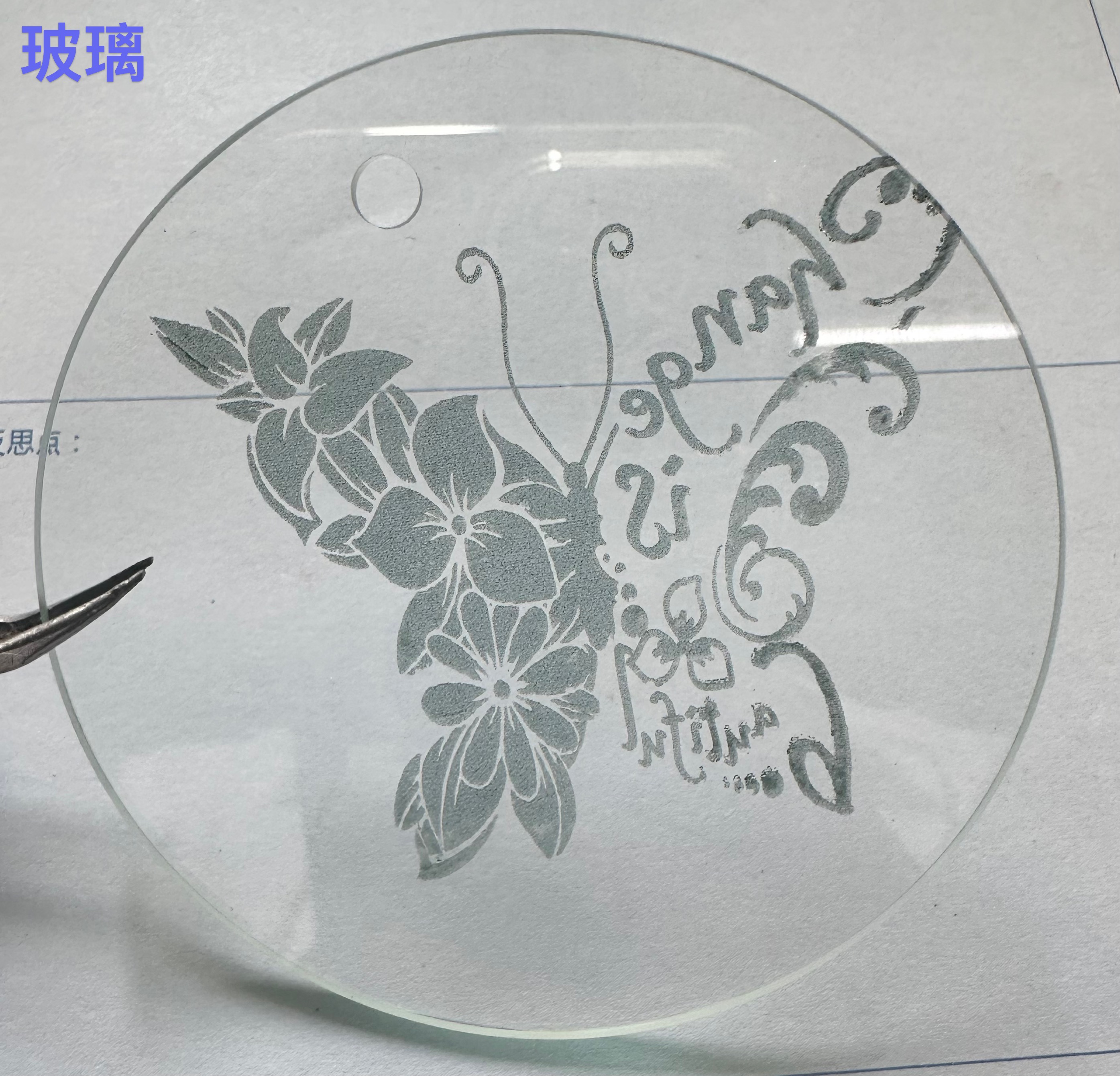

Ceramics and glass: Under a certain power, ceramics and glass can be carved, and exquisite patterns and patterns can be made. However, due to the higher hardness of these materials, higher laser energies and finer parameter adjustments are required.

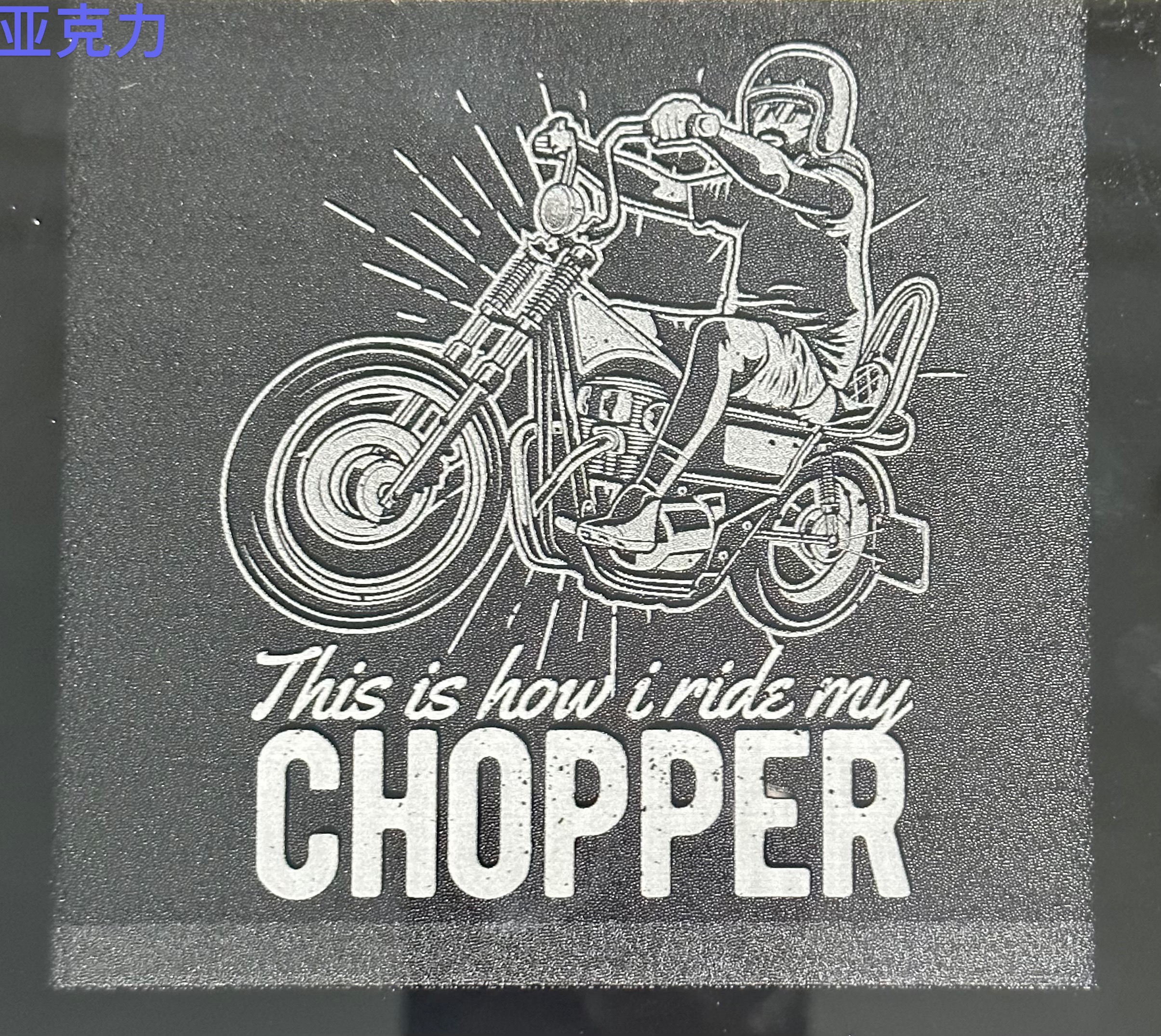

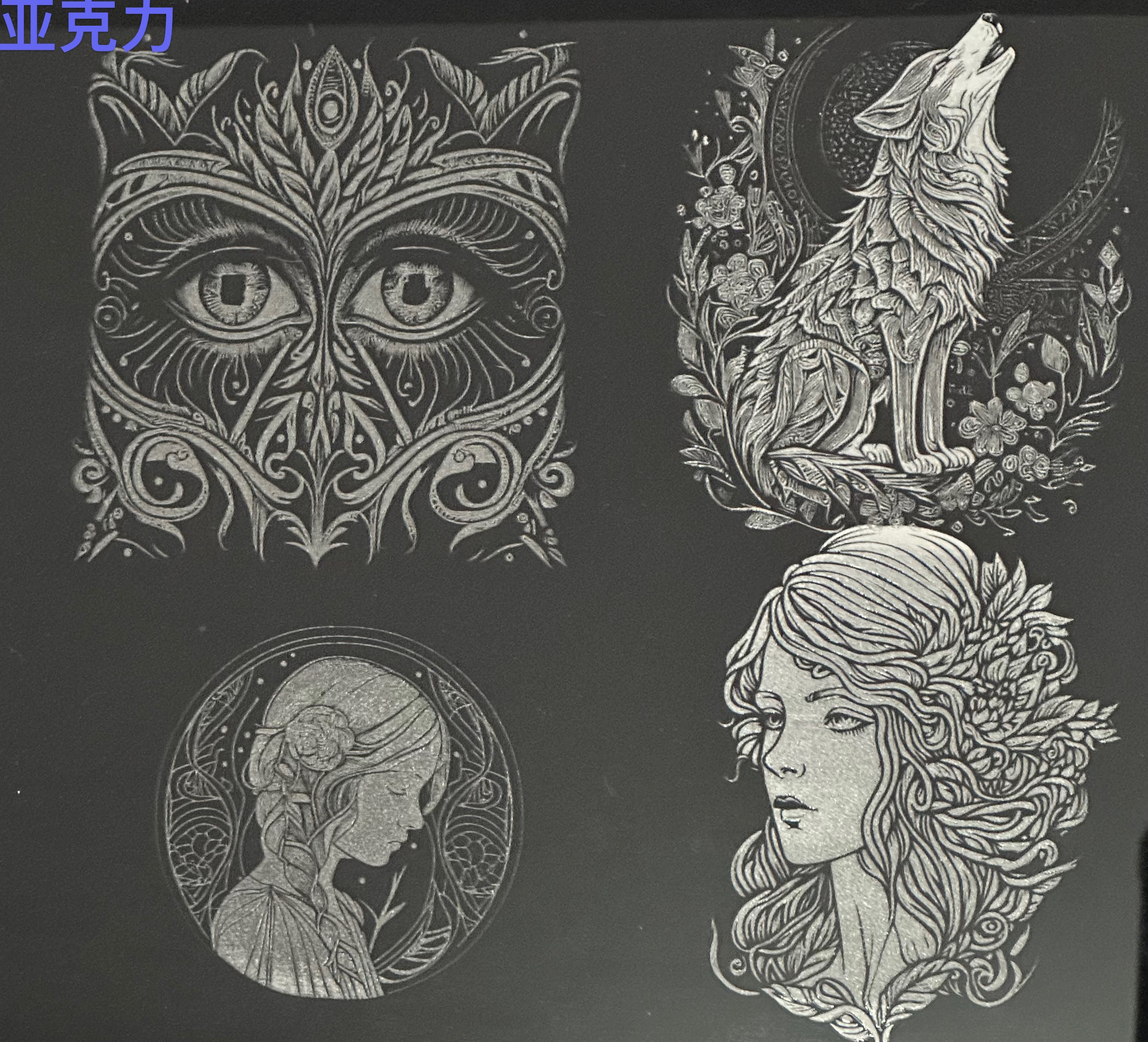

Plastic materials: Plastic products are often engraved with 450nm blue laser for patterns and texts, and the engraving effect is good.

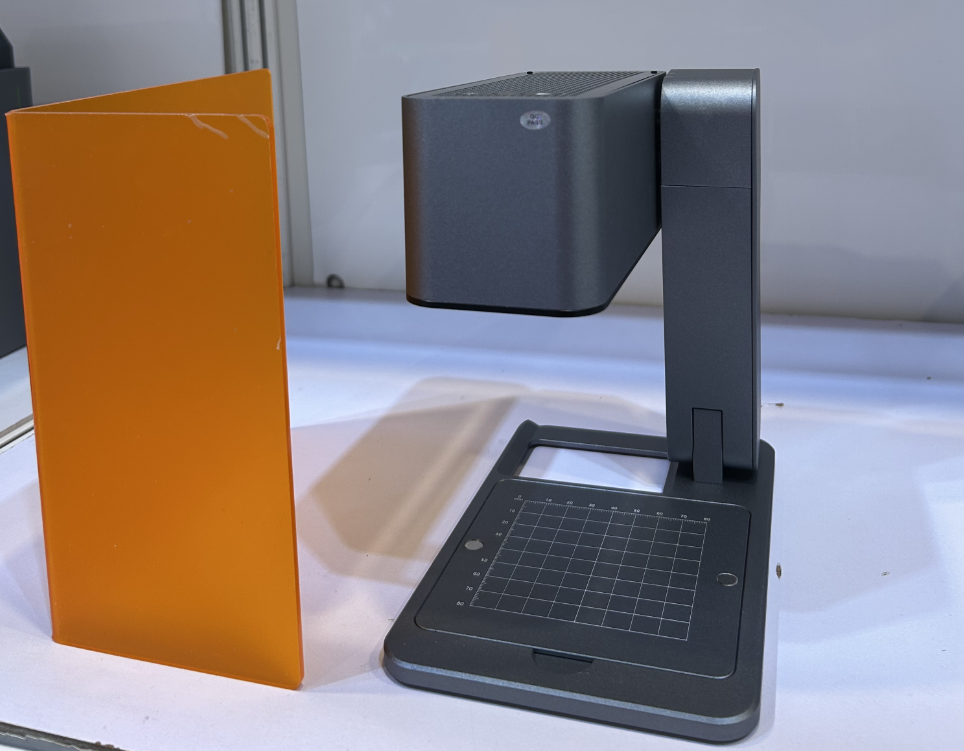

Equipment & Tools

Blue laser: Choose a 450nm blue laser with the right power, such as 2W, 5W, 10W, etc., the higher the power, the stronger the engraving ability, but it should also be decided according to the actual needs and budget. Common products include related lasers of Lanyu Laser, Caplin and other brands.

Laser engraving machine: It needs to be equipped with an engraving machine that can precisely control the movement of the laser head, and its control system must be able to accurately read and execute the instructions of the engraving file. Some desktop-level laser engraving machines are very suitable for DIY engraving, such as Xiaomi Mijia laser engraving machine, Dangdangcion intelligent laser engraving machine, etc.

Assistive tools: such as protective eyewear to protect the eyes from laser damage; heat dissipation equipment to help the laser maintain a stable temperature while operating; There are also jigs that are used to hold the material to be engraved and prevent it from moving during the engraving process.

Design & Software

Graphic design: Use graphic design software, such as Adobe Illustrator, CorelDRAW, etc., to design the pattern, text, or image you want to engrave. You can also download some ready-made design files from the Internet and modify and adjust them according to your needs.

File Conversion: Convert the designed pattern file into a format that the laser engraver can recognize, such as G-code. Some laser engraving machines come with software that can directly convert the format, or you can use a special conversion tool software.

Engraving steps

Prepare the materials and equipment: Prepare the materials to be engraved and fix them on the workbench of the laser engraving machine. Check whether the laser, engraving machine and other equipment are working properly to ensure that the optical path system is accurate.

Set parameters: According to the type of material, thickness and engraving requirements, set the appropriate laser power, engraving speed, pulse frequency and other parameters in the control software of the engraving machine. In general, lower power and higher speed should be used for thinner, flammable materials; For thicker, harder materials, it is necessary to increase the power and reduce the speed appropriately.

Import file: Import the converted engraving file into the control system of the laser engraving machine, and set the starting position of the engraving and other related parameters.

Engraving: After confirming that everything is correct, start the laser engraving machine and start the engraving operation. In the process of engraving, it is necessary to keep observing to ensure that the engraving effect meets expectations, and if you find a problem, you should stop the engraving in time and adjust the parameters before continuing.

Complete the engraving: After the engraving is completed, turn off the power of the laser engraving machine and laser, wait for the material to cool down, remove the engraved items, and clean up the debris and dust on the workbench.

Real-life Scenario Images

Online

Phone

13113150112

laser2326

asbang-laser@139.com