Laser Cutting

1. 450nm blue light cutting principle

450nm blue light is in the blue band of visible light, and its cutting principle is based on high energy density characteristics. When a 450nm blue laser emits a laser beam, it is focused into a very small area of the surface of the material to be cut through a specific optical focusing system. At this time, the area instantly absorbs a large amount of light energy, and the light energy is quickly converted into heat energy, causing the temperature of the material to rise sharply. In a very short time, the material reaches the melting point or even the boiling point, and part of the material is directly sublimated from the solid state to the gaseous state, forming the removal of the material, and the cutting of the material is realized as the laser head moves according to the preset trajectory. For example, when cutting paper, the energy of the laser quickly heats up the paper fibers, carbonizes, and vaporizes, thereby separating the paper; For metal materials, the high heat of the laser makes the metal partially melt, and under the blowing of auxiliary gases (such as oxygen, nitrogen, etc., choose the appropriate gas according to different metals), the molten metal is blown away from the cutting area to complete the cutting process.

2. Applicable materials (transparent materials need to be colored or pasted with auxiliary materials for cutting)

Organic materials

Paper: All kinds of paper such as ordinary printing paper, cardboard, art paper and so on can be cut using 450nm blue light (except white paper). Because the paper absorbs blue light better, it cuts faster and has neater edges. For example, when making paper crafts, greeting cards, and paper sculptures, it is easy to cut out complex patterns and shapes, such as delicate snowflake patterns and human outlines.

Wood: Thin wood boards such as basswood planks and paulownia planks, when the thickness is less than a few millimeters, 450nm blue light can be effectively cut. During the cutting process, the laser carbonizes and separates the wood fibers, which can be used to make small wooden ornaments, wooden puzzles, model parts, etc., and there will be slight carbonization marks on the edges of the wood after cutting, but they can be eliminated after sanding.

Leather: Both natural and faux leather can be cut by 450nm blue light. When cutting leather, the energy of the laser changes the molecular structure of the leather surface and cuts it, which is suitable for making leather jewelry, such as leather keychains, leather carving pattern cutting, etc., the cutting edge is relatively neat and can prevent the wear and spread of the leather edge to a certain extent.

plastic materials

Non-transparent acrylic: Non-transparent acrylic sheet is a common plastic cutting material, and when 450nm blue light cuts acrylic, it can obtain a smooth cutting surface. It can be used to make acrylic display stands, decorative honor plates, small acrylic crafts, etc. Different thicknesses of acrylic sheets need to adjust different laser power and cutting speed, generally thinner acrylic sheets cut faster, such as 3mm thick acrylic sheets are more efficient than 5mm thick ones.

PVC Plastics: PVC sheets and pipes can also be cut by 450nm blue light in a range of thicknesses. When cutting PVC, you need to pay attention to ventilation as a small amount of harmful gases may be produced during the cutting process. It can be used to make some PVC plastic models, plastic parts, etc.

Partially brittle material

Glass: For thinner glass sheets, such as process glass with a thickness of 1 - 2mm, 450nm blue light can be cut with precisely controlled parameters. The cutting principle is to use the thermal action of the laser to make the glass locally heated and expand, generate stress, and form cracks along the preset cutting line to achieve separation. It can be used to make glass handicrafts, cutting glass lenses, etc., but it requires high precision in operation technology and equipment.

Ceramic: Thin ceramic sheets or ceramic sheets also have some cutability. When cutting ceramics with 450nm blue light, the laser energy causes the ceramic material to partially melt and vaporize the ceramic material, and then realize the cutting. It can be used to make ceramic ornaments and small ceramic parts, but it is necessary to prevent the ceramic piece from cracking due to thermal stress during the cutting process.

3. Equipment and tools

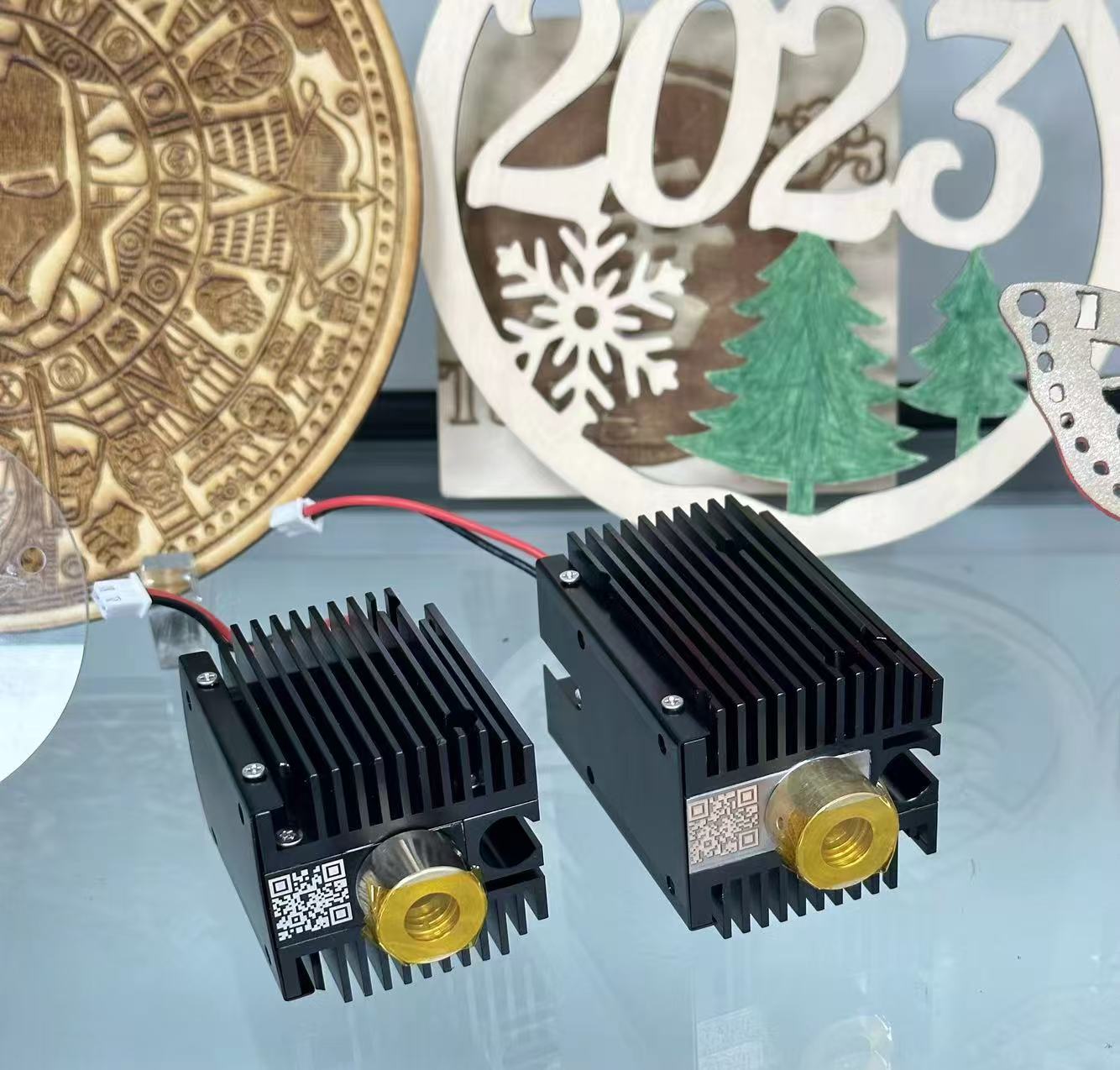

Blue laser: You need to choose a 450nm blue laser with the appropriate power, and the common power is 2W, 5W, 10W, etc. The higher the power, the greater the cutting power, but for DIY applications, a 2 - 5W laser may be sufficient and the cost is relatively low if the material being cut is thinner and softer (e.g. paper, thin leather). If you want to cut thicker acrylic boards, wooden boards, etc., you will need a laser with a power of 5W and above.

Laser engraving machine (or cutting machine): It needs to be equipped with equipment that can accurately control the movement trajectory of the laser head, and its control system can read the cutting file (such as the G-code converted from common AI and DXF format files) and accurately execute the instructions. For example, Dangdang Lix's intelligent laser engraving machine L1 has 10W and 20W blue laser units (450nm wavelength), which can be engraved and cut with a large working area, which can meet the needs of DIY cutting of a certain scale; There are also some small desktop laser cutters that are small in size and relatively affordable, making them suitable for individuals to perform simple DIY cutting operations at home.

Auxiliary tools

Protective glasses: 450nm blue light is harmful to the eyes, and special blue light protective glasses must be worn to avoid direct laser exposure to the eyes and protect eyesight.

Heat dissipation equipment: The laser will generate heat during the working process, and heat dissipation equipment (such as cooling fan, water cooling device, etc., selected according to the laser power and heat dissipation requirements) is required to help the laser maintain a stable working temperature and prevent overheating from affecting the laser life and cutting effect.

Fixed fixture: It is used to firmly fix the material to be cut, prevent the displacement of the material during the cutting process, and ensure the cutting accuracy. For example, use Fixing materials such as C-clamps and strong double-sided tape.

Smoke exhaust device: Smoke and odor may be generated during the cutting process, especially when cutting organic materials, the smoke exhaust device can discharge the smoke out of the outdoor in time to keep the working environment clean and safe. A small tabletop fume extraction fan can be used, or a special fume extraction duct system can be connected.

4. Design and software Pattern design: Use graphic design software such as Adobe Illustrator, CorelDRAW, etc. to design cutting patterns. You can draw unique graphics according to your own creativity, such as designing a personalized keychain pattern, a complex paper carving pattern, etc.; It is also possible to download ready-made vector graphics materials from the Internet, and then modify and adjust them according to actual cutting needs. For example, when designing a wooden puzzle, you can find interesting patterns of animals, buildings, and other patterns from the Internet, and adjust the size, shape, and layout in the software. File conversion: The designed pattern file needs to be converted to a format that can be recognized by the laser engraver (cutting machine), usually a G-code. For example, after importing the AI file into the built-in software of the device, the cutting parameters can b

Real-life Scenario Images

Online

Phone

13113150112

laser2326

asbang-laser@139.com